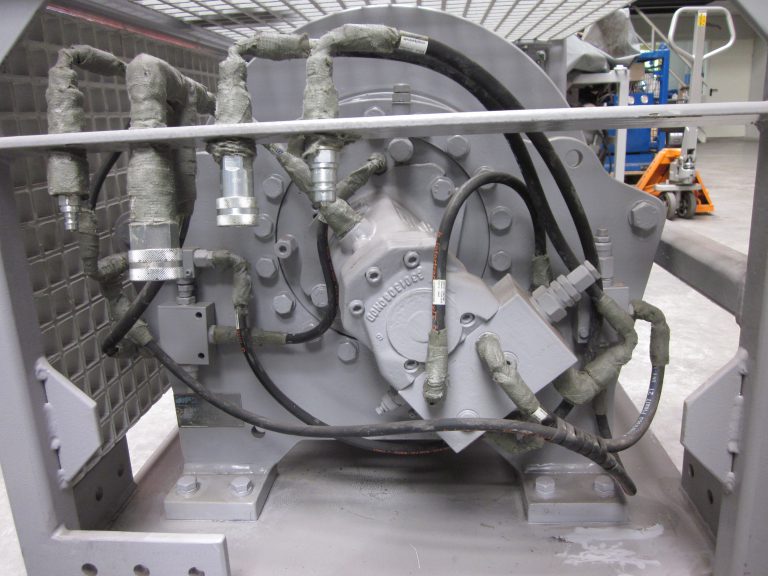

Hydraulic piping

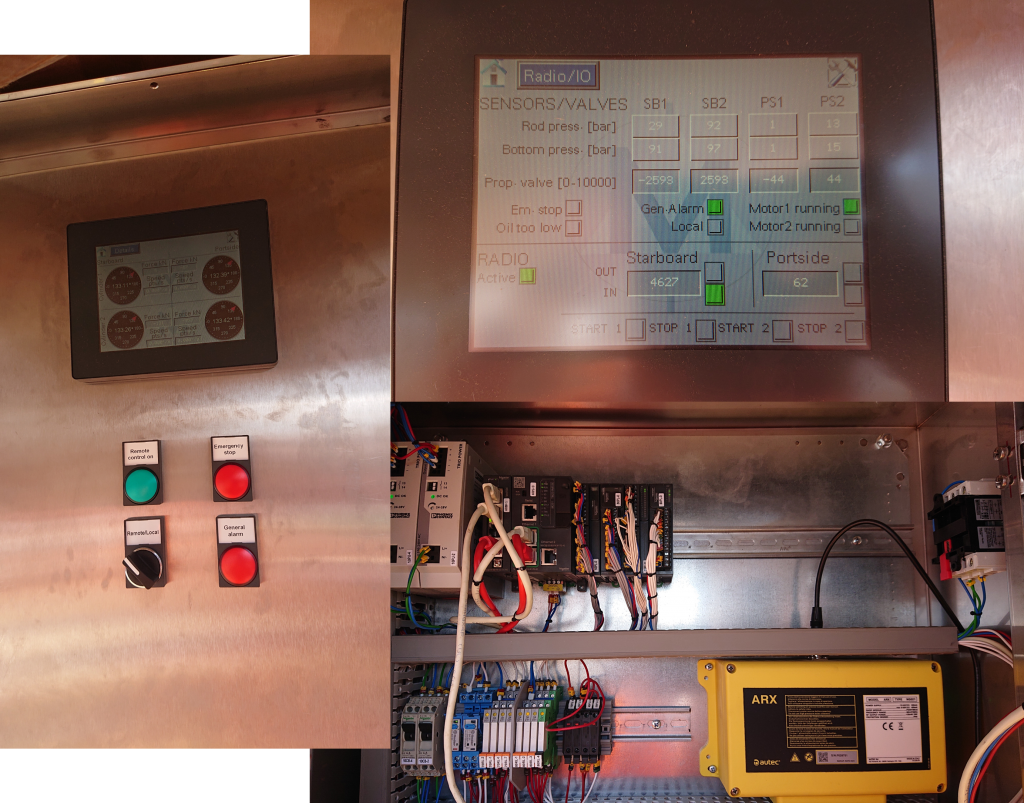

Muns Techniek is a system integrator for Hydraulic systems and Electrical controls. With more than 25 years of experience we offer Hydraulic and Electric Solutions for projects in the Maritime, Offshore and Industry.

Customer

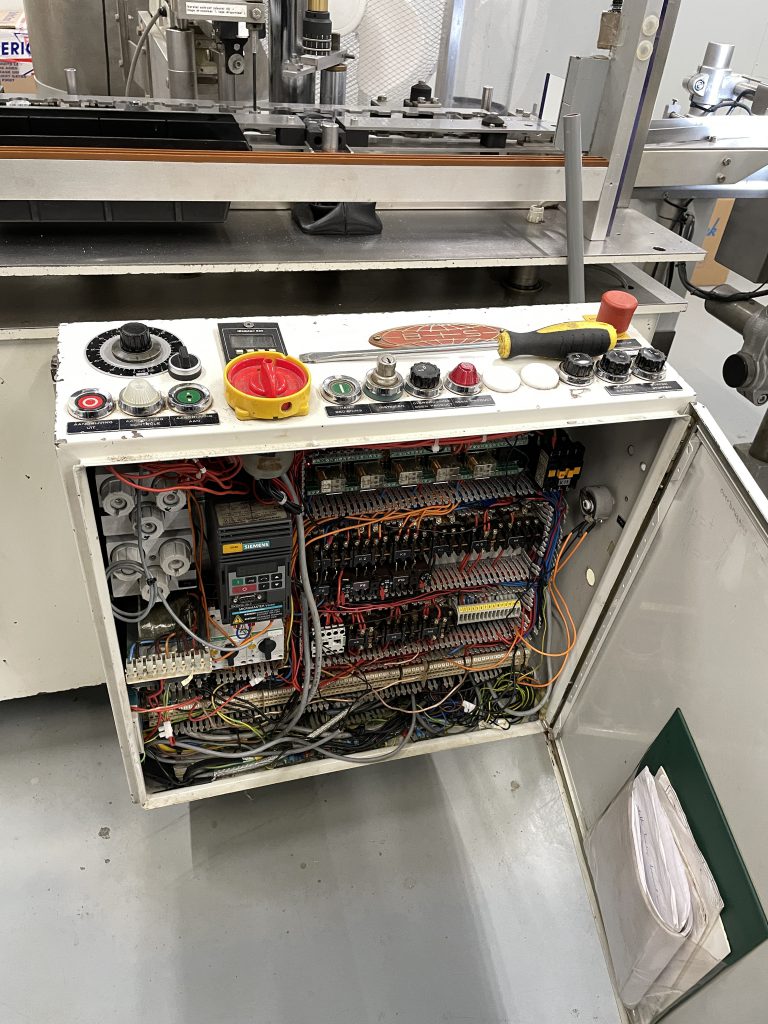

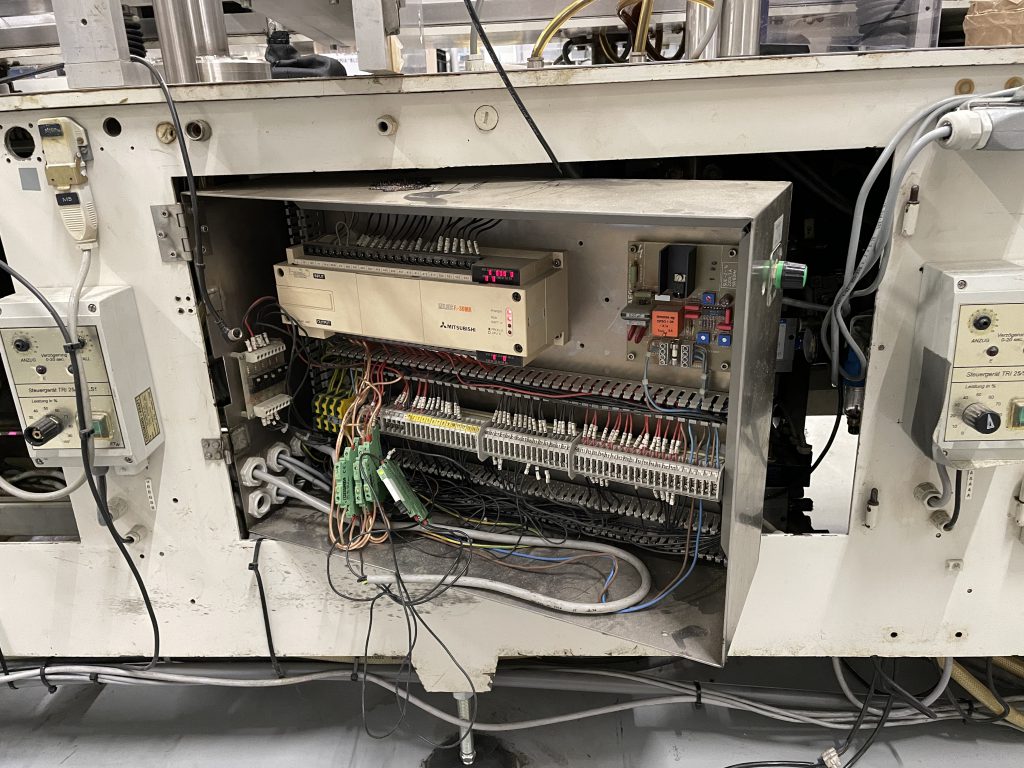

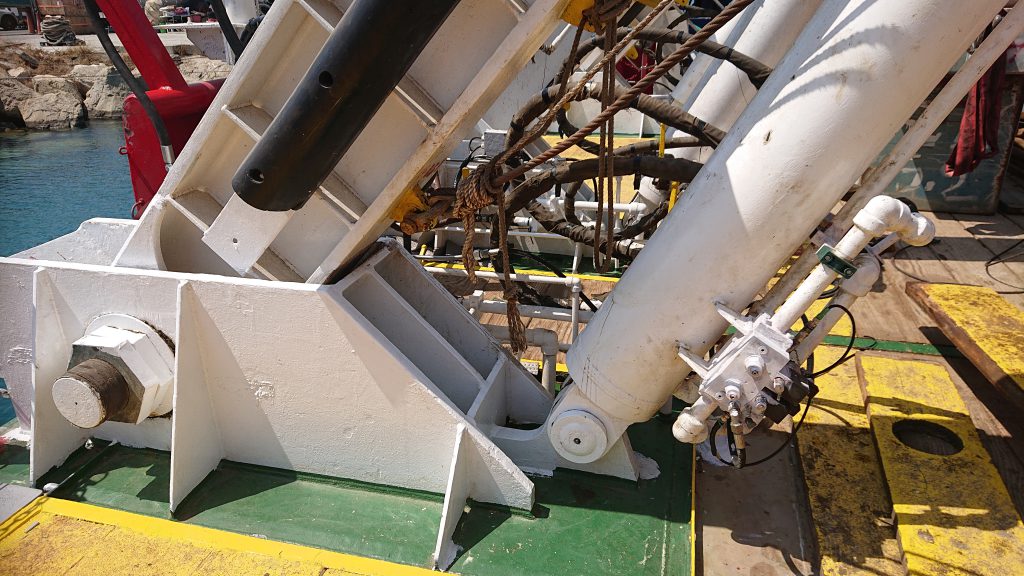

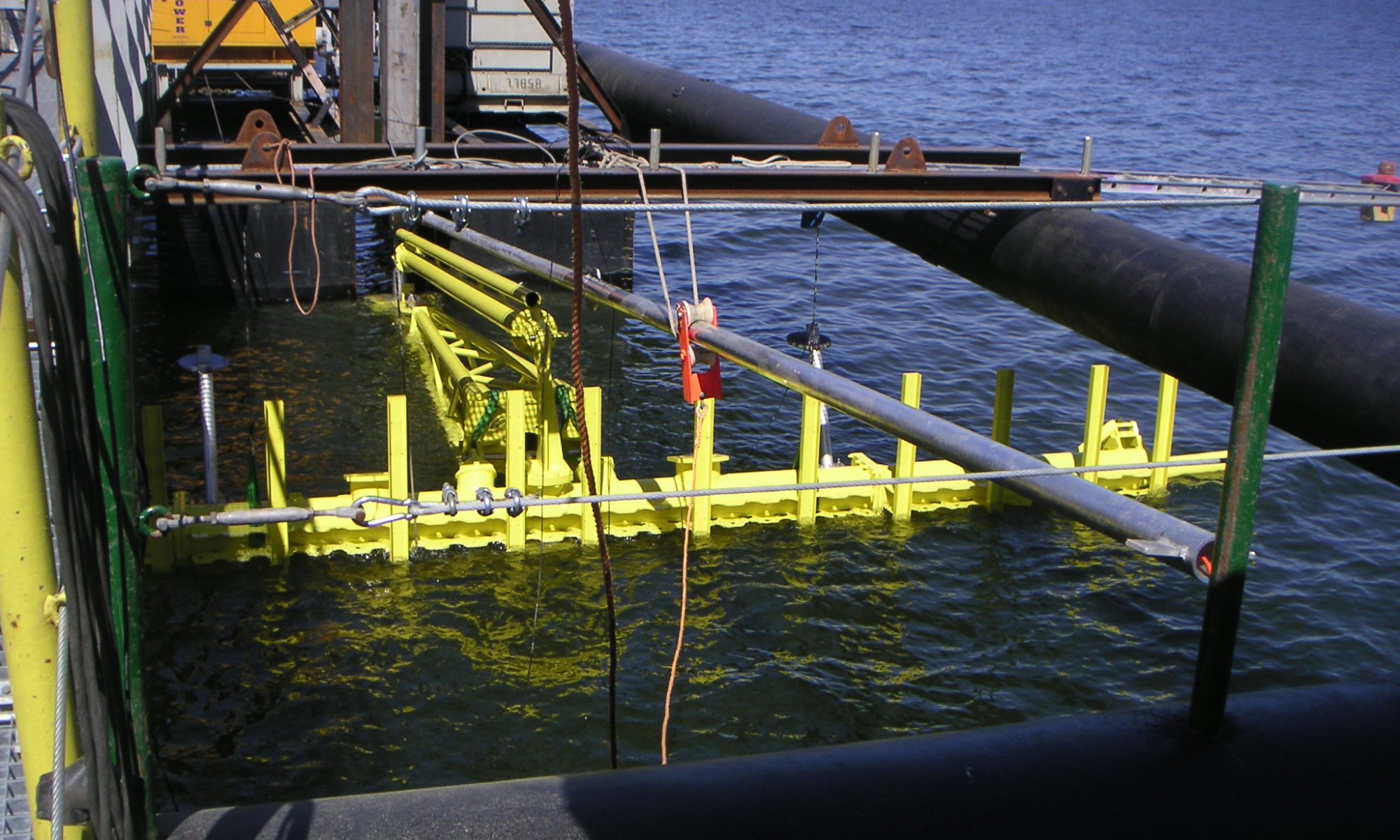

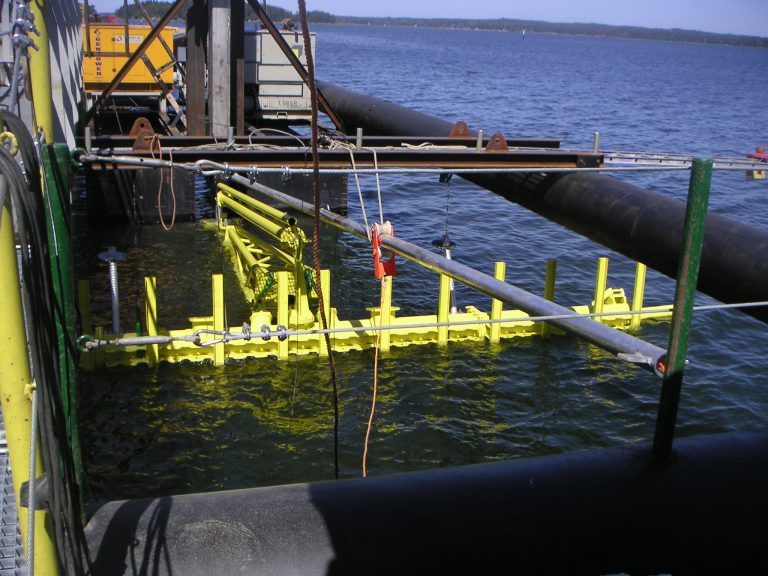

Hydraulic piping is an essential part of hydraulic systems. These pipes must be custom-made and fitted to the rooms they will be placed in.

The piping must cross spaces as efficiently as possible, must be easily accessible and must be installed properly.

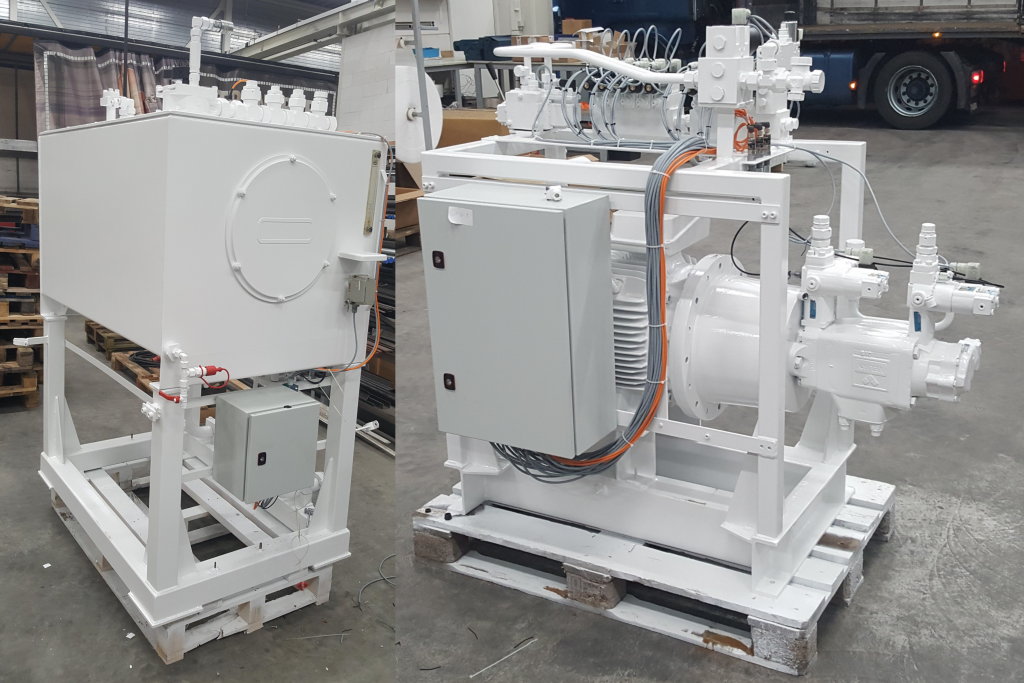

Muns Techniek solution

Muns Techniek has a lot of experience in making hydraulic piping.

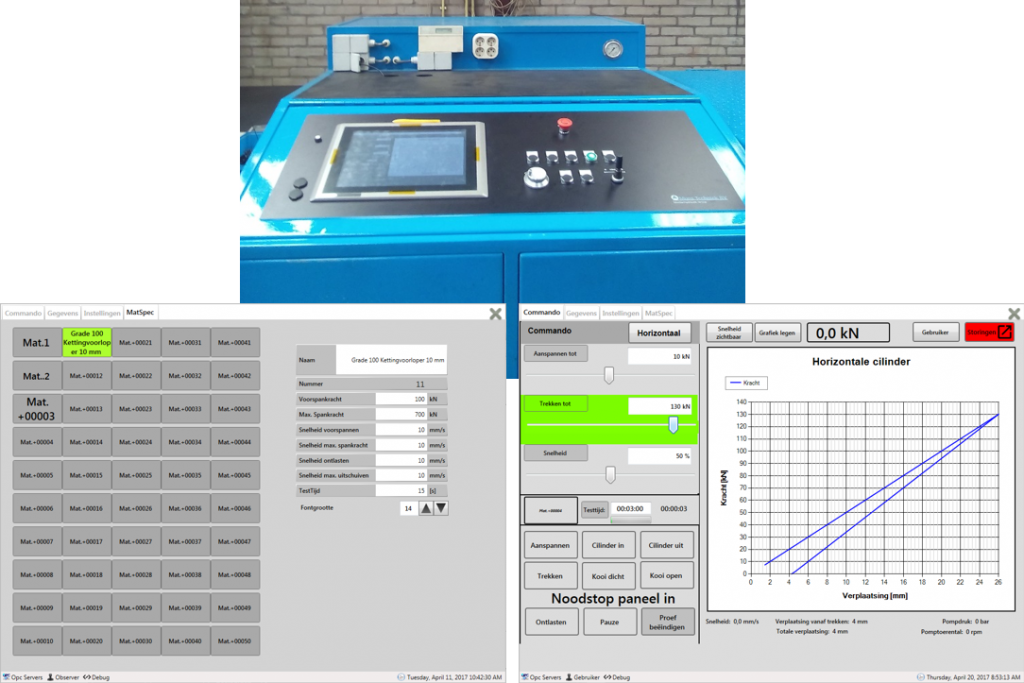

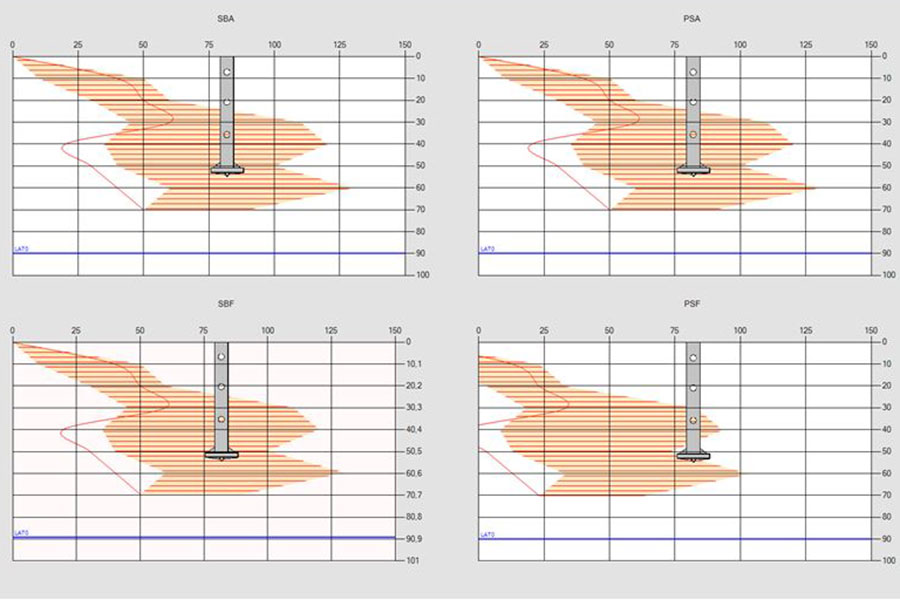

Our employees can accurately design the piping on location. The pipes are then made in our workshop and pressure tested.

Once the pipes have been tested, they can be installed in on location. The system is then ready for a final test.

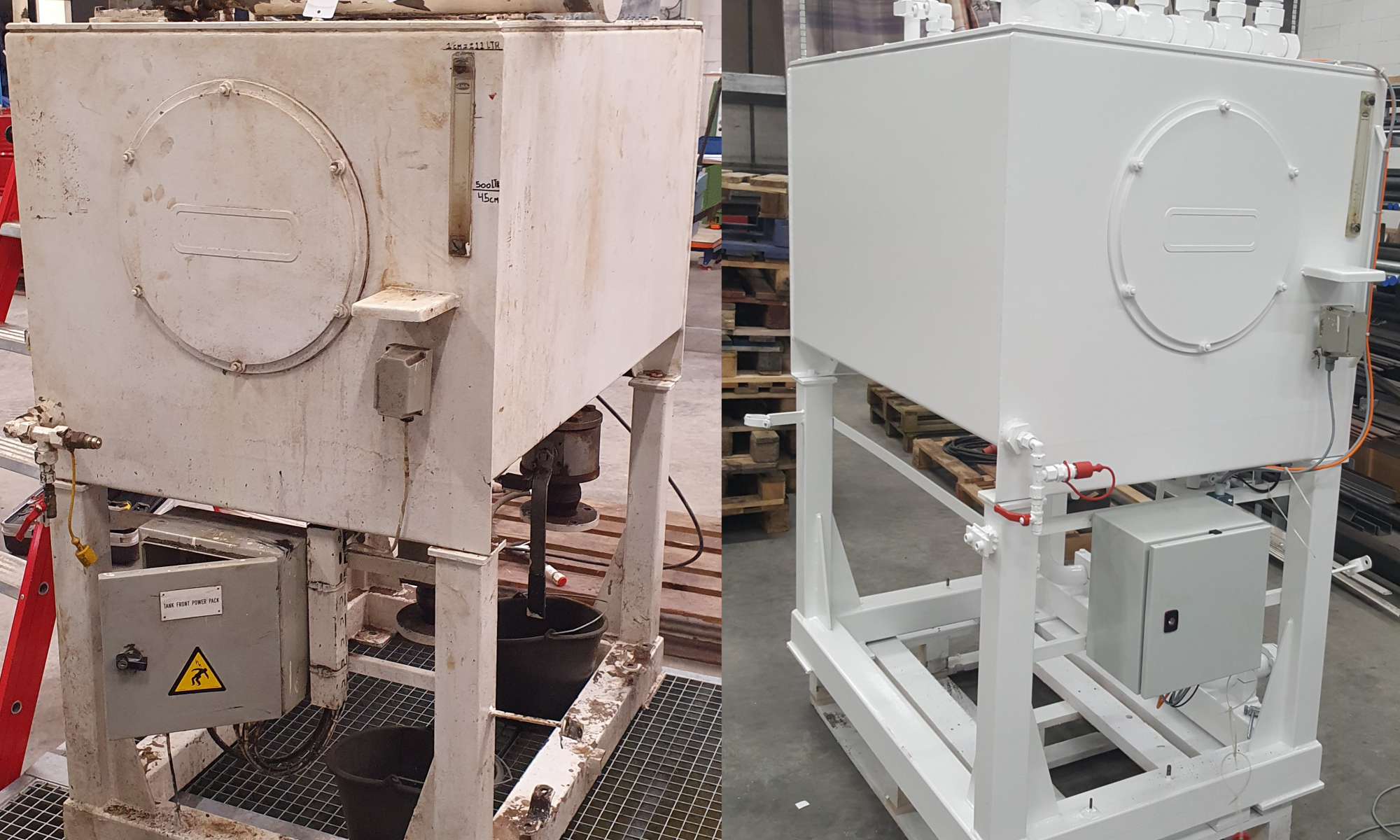

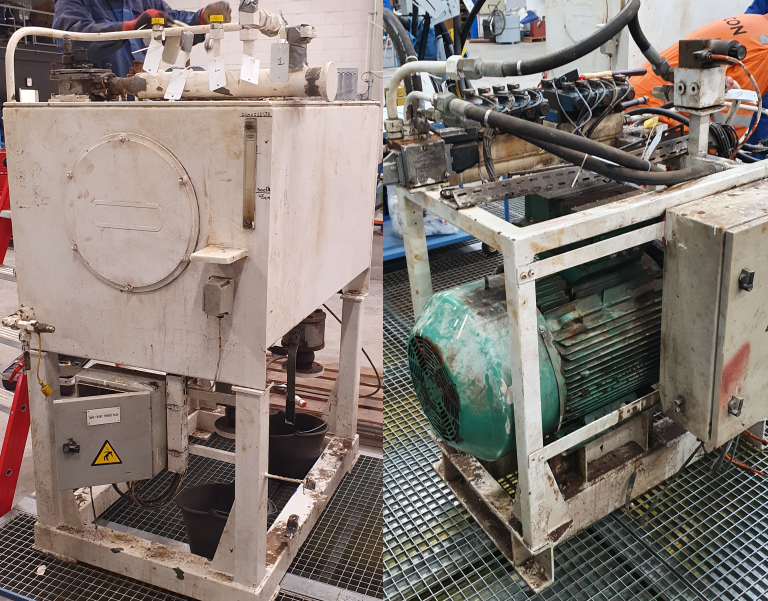

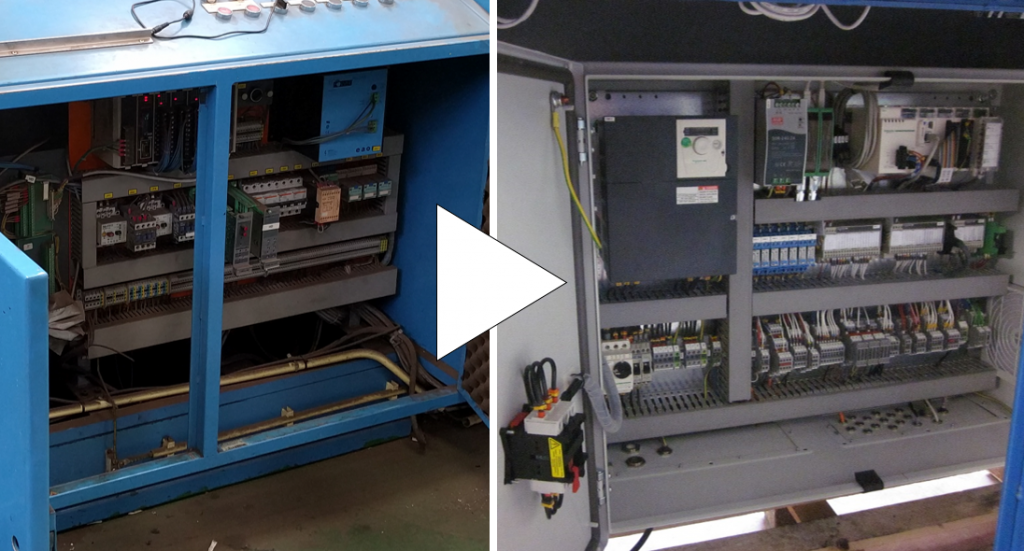

In addition to installing new systems, we also help in repairing leaks or overhauling systems.

Result

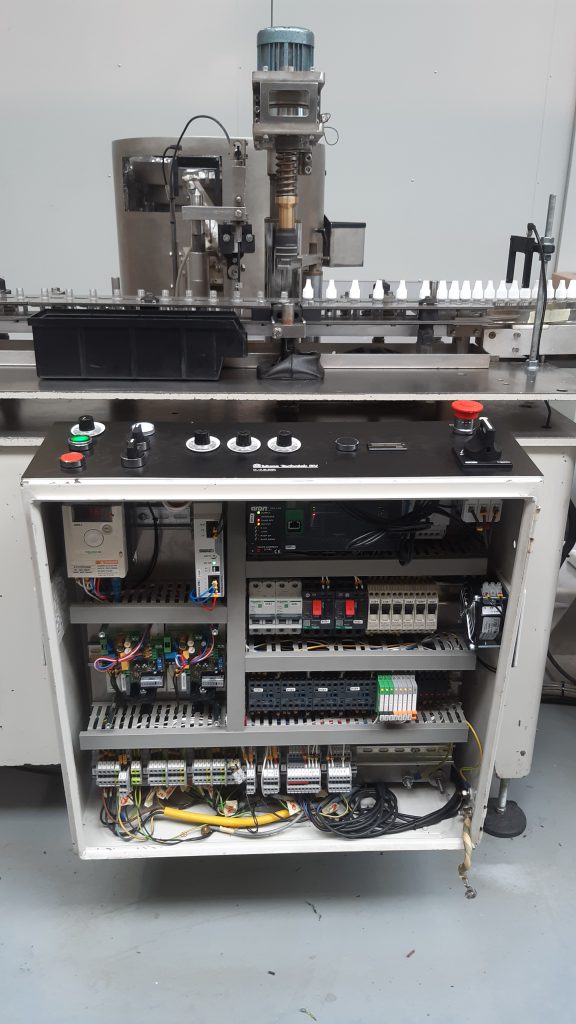

Muns Techniek has already provided hydraulic piping for many projects. These projects vary from a small number of pipes on hydraulic winches, to the piping of large ships such as hoppers and split barges.

In our workshop we can bend hydraulic pipes up to 60mm. If necessary, these pipes can be equipped with bördel or cutting fittings.