Customized winches

Muns Techniek is a system integrator for Hydraulic systems and Electrical controls. With more than 25 years of experience we offer Hydraulic and Electric Solutions for projects in the Maritime, Offshore and Industry.

Customer

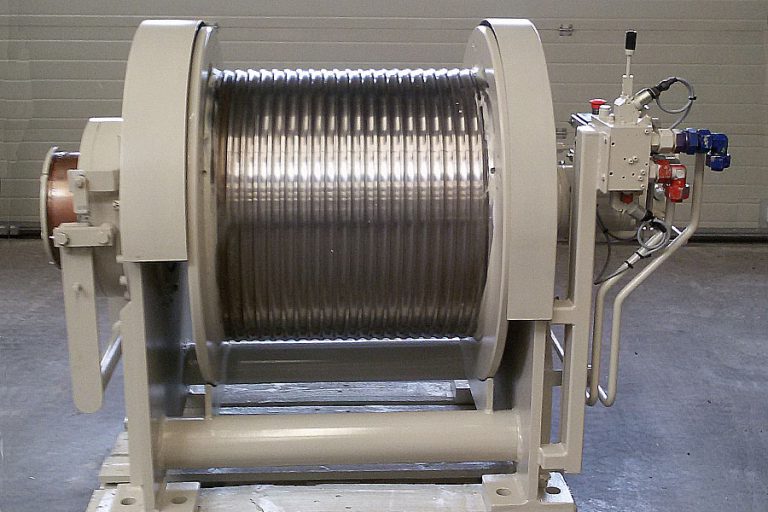

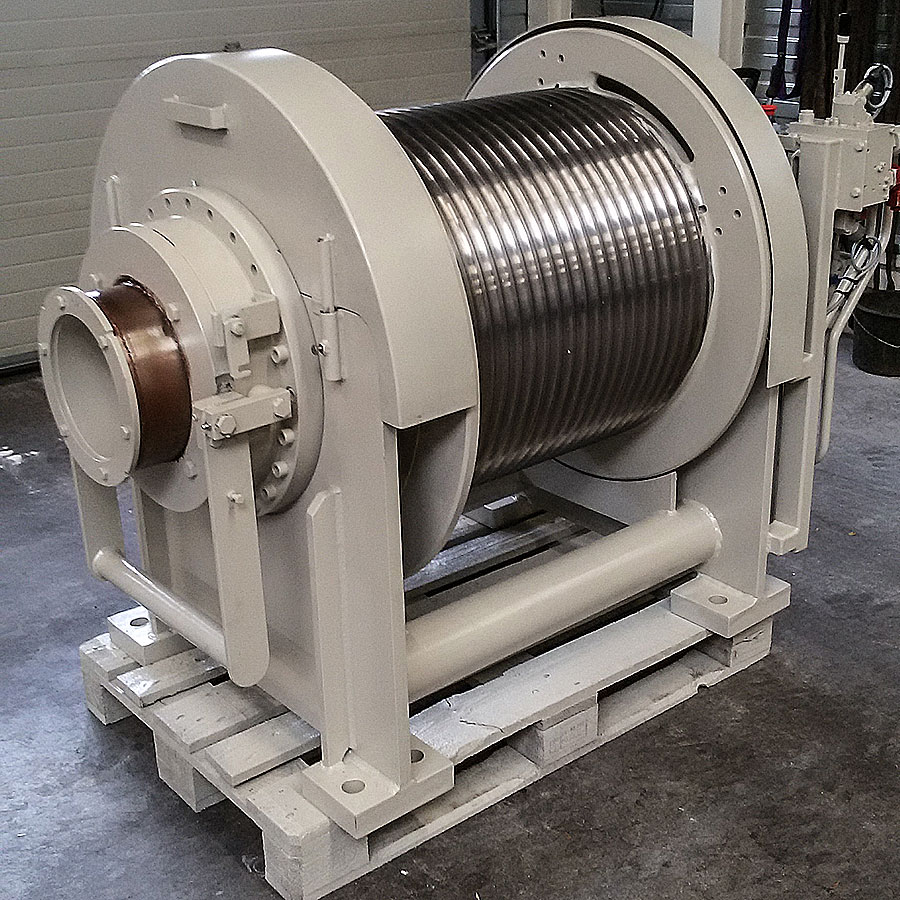

Our client, a major contractor in the dredging industry, was looking for a winch for her dredging equipment. Everything that was available as standard in the market did not meet his requirements.

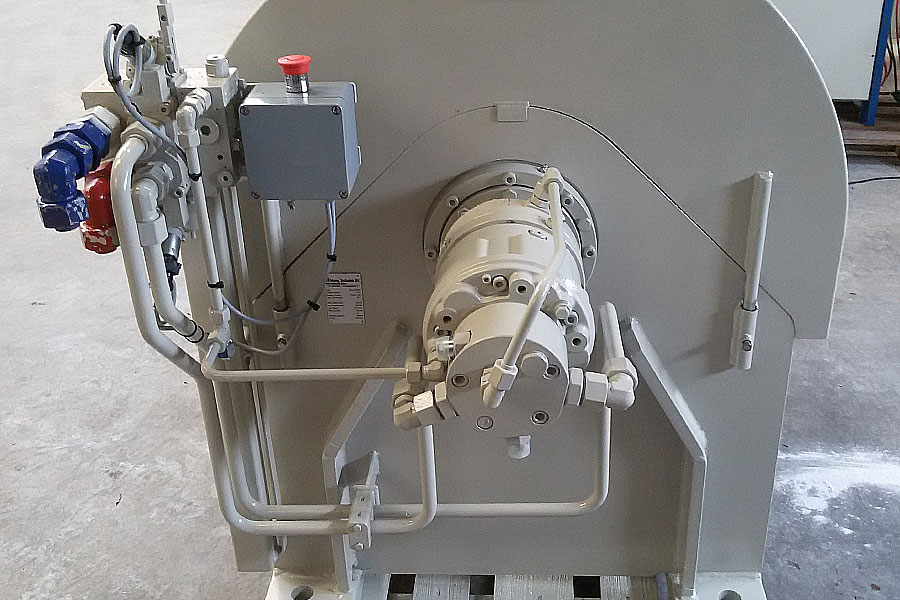

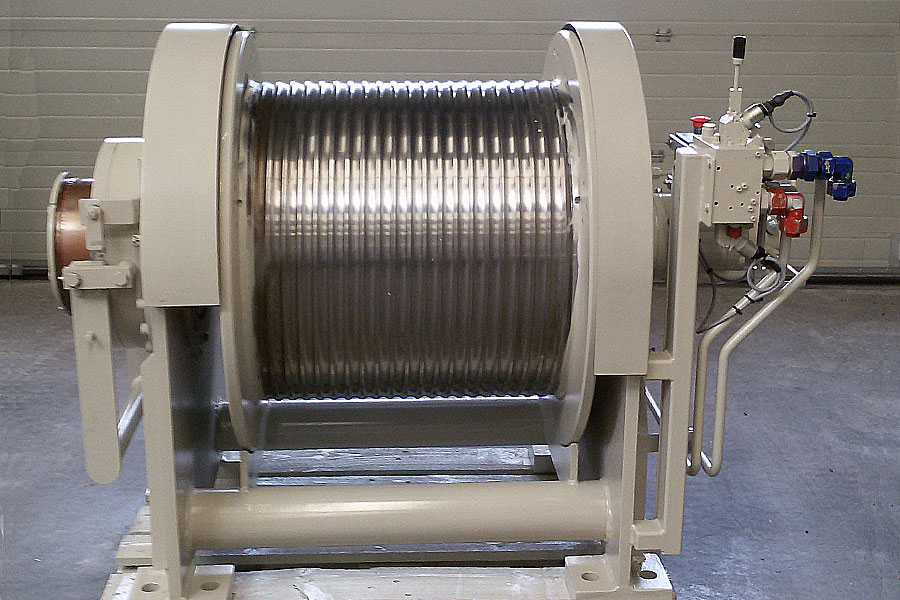

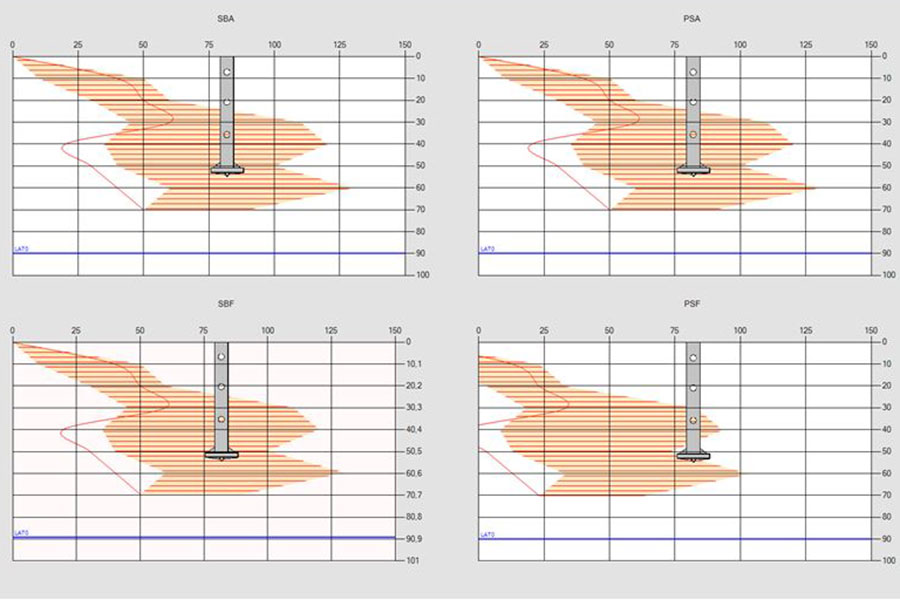

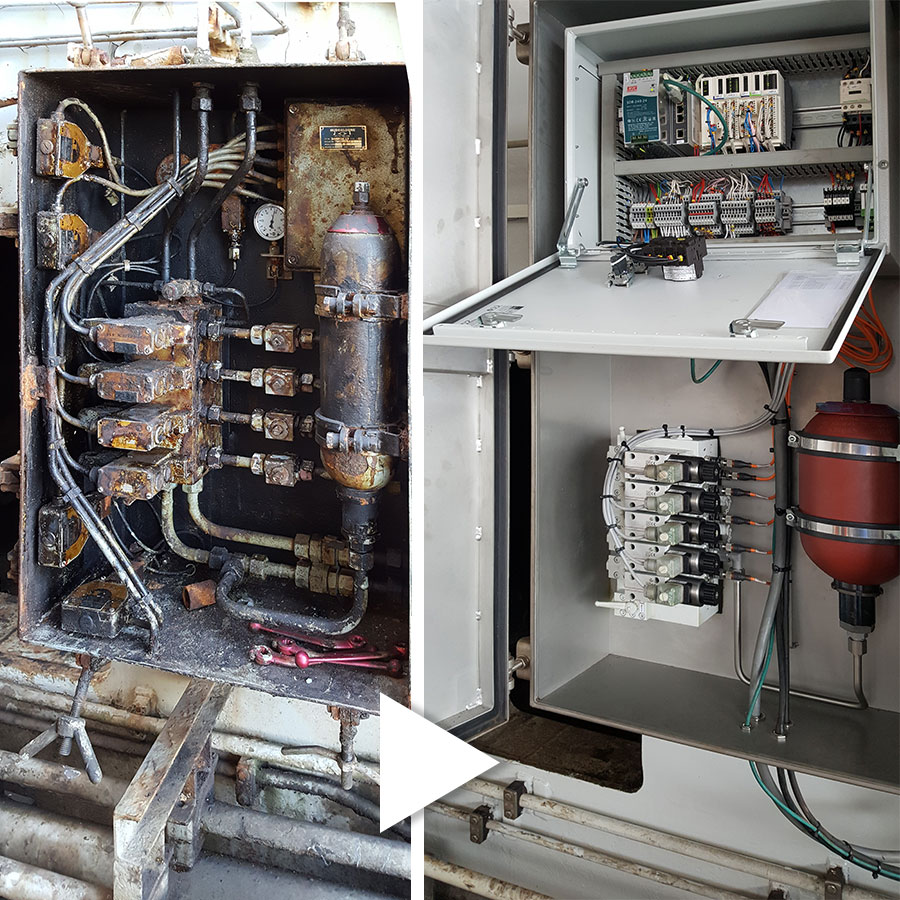

Muns Techniek solution

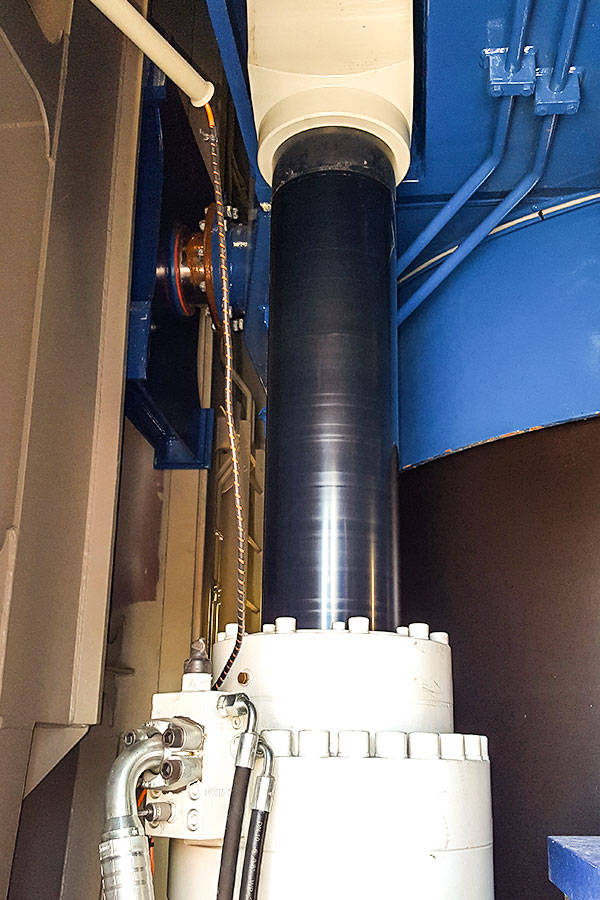

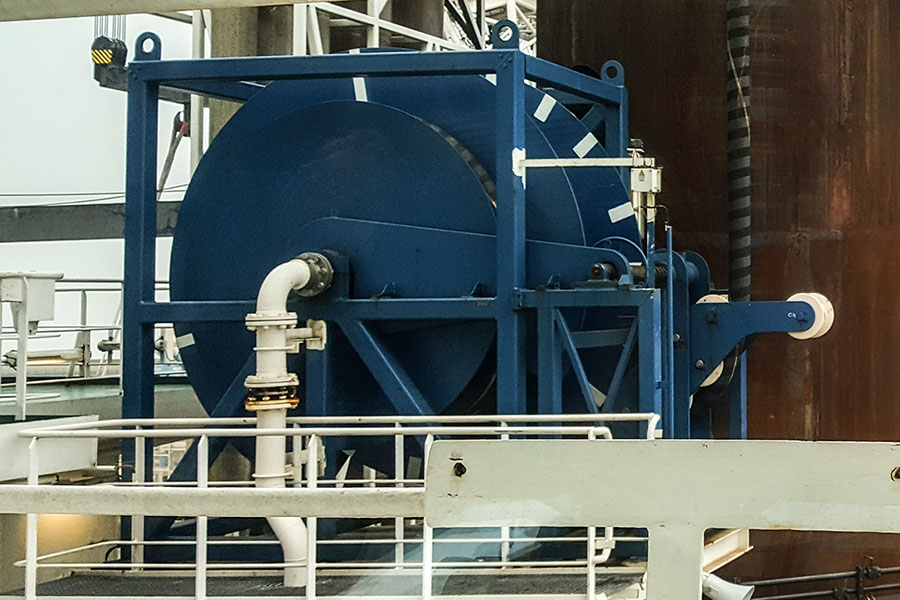

Muns Techniek was approached and of course a solution was developed. Muns Techniek has also supplied several winches for various applications in the past. Customized and integrated with the hydraulic system that was already installed on board.

Benefits: Innovation

No major adjustments were needed on board, because the winch exactly met the demands of the customer. Full integration with the controls was also included.

Result

Customer was very satisfied, and has since ordered 3 winches from Muns Techniek. The customer realizes that they can entrust their technical challenges to Muns Techniek. Whether it’s a winch or a complete jack-up system, Muns Techniek delivers the solution.