- +31 (0)183 307 000

- info@munstechniek.nl

- Mo - Fri: 8:00 - 18:00

In many of our previous projects that included software control and an HMI (Human Machine Interface), we ran into limitations of the HMI software. Often what we wanted to implement was either very difficult, or just not possible.

Additionally, when a customer wanted something added to their system, it happened that the software licence had to be upgraded. The additions would cause the HMI to exceed the limit of the current licence.

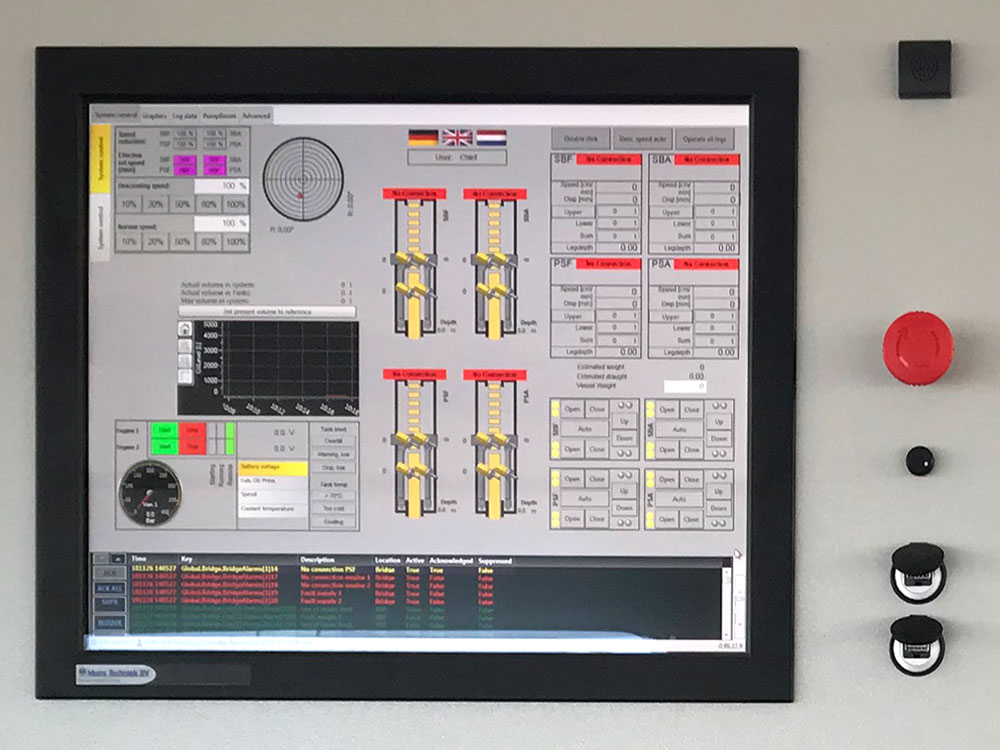

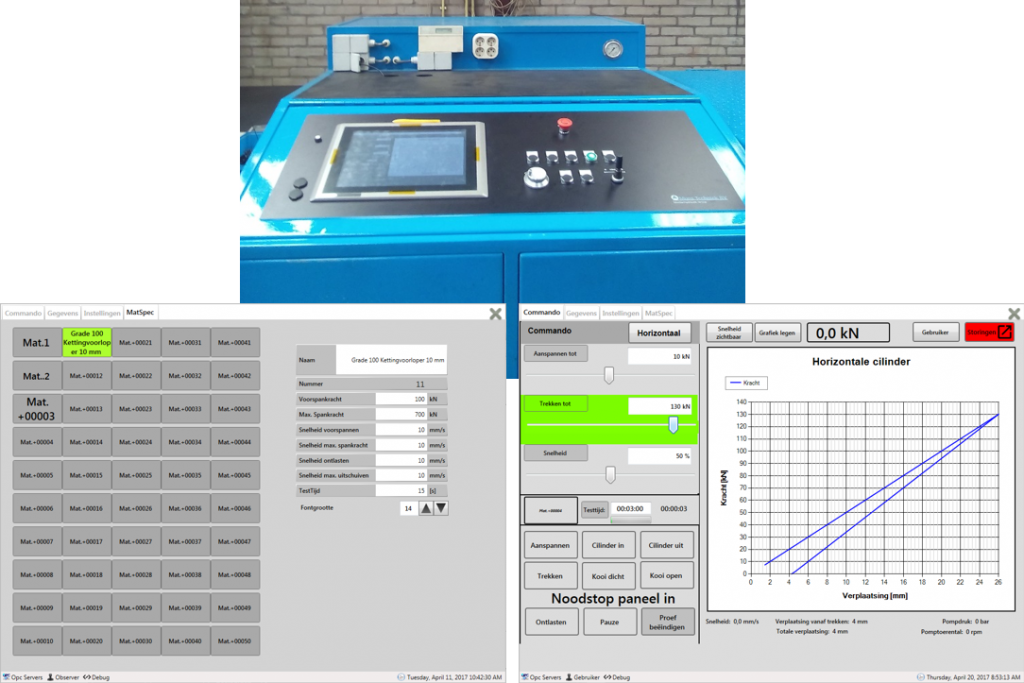

To ensure we did not have such issues in the future, our software engineers developed our own HMI software, the Muns Operating System software. Because the development is done in-house, we have complete control over the possibilities and extension of the software.

The advantage of our own software is that besides including the standard functionality of an HMI software, the software itself has been more specifically designed for our own systems. In addition, it allows us to add new functions when necessary.

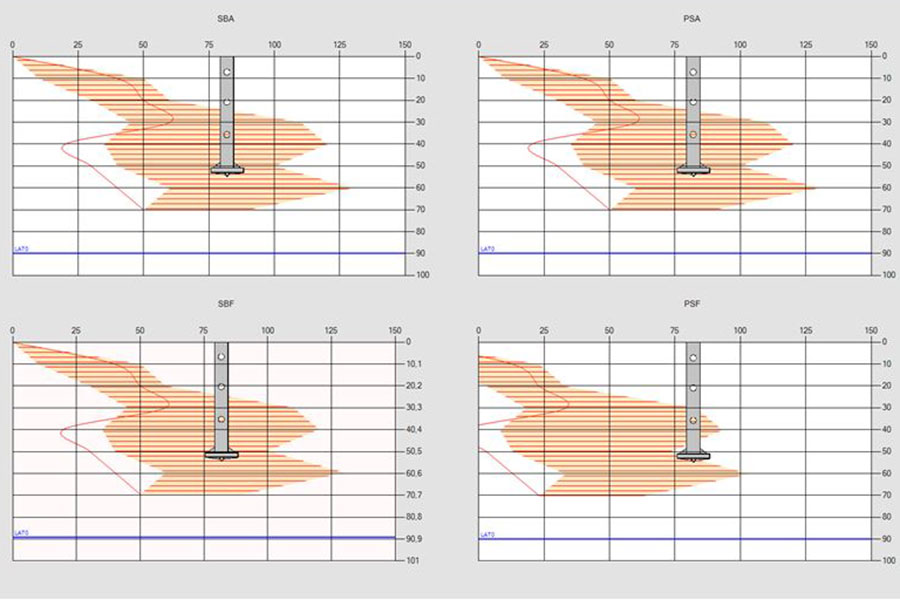

Because the software is developed in-house, other software developed by our engines, such as the survey chart software, can easily be integrated. This ensures that the integrated software becomes a part of the HMI, instead of just a stand-alone program that is called upon by the HMI.

This new software has now been installed in a number of our more recent projects. During the commissioning of the systems, the software has been thoroughly tested. This ensures that the HMIs of these systems are easy to use and work as intended.