- +31 (0)183 307 000

- info@munstechniek.nl

- Mo - Fri: 8:00 - 18:00

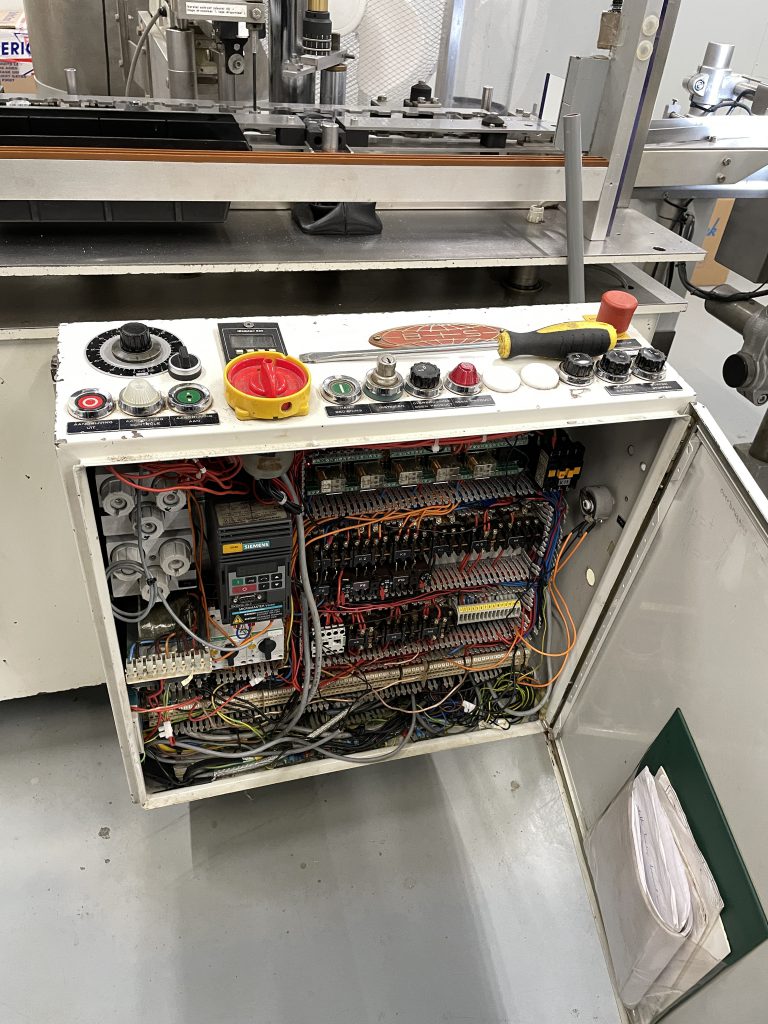

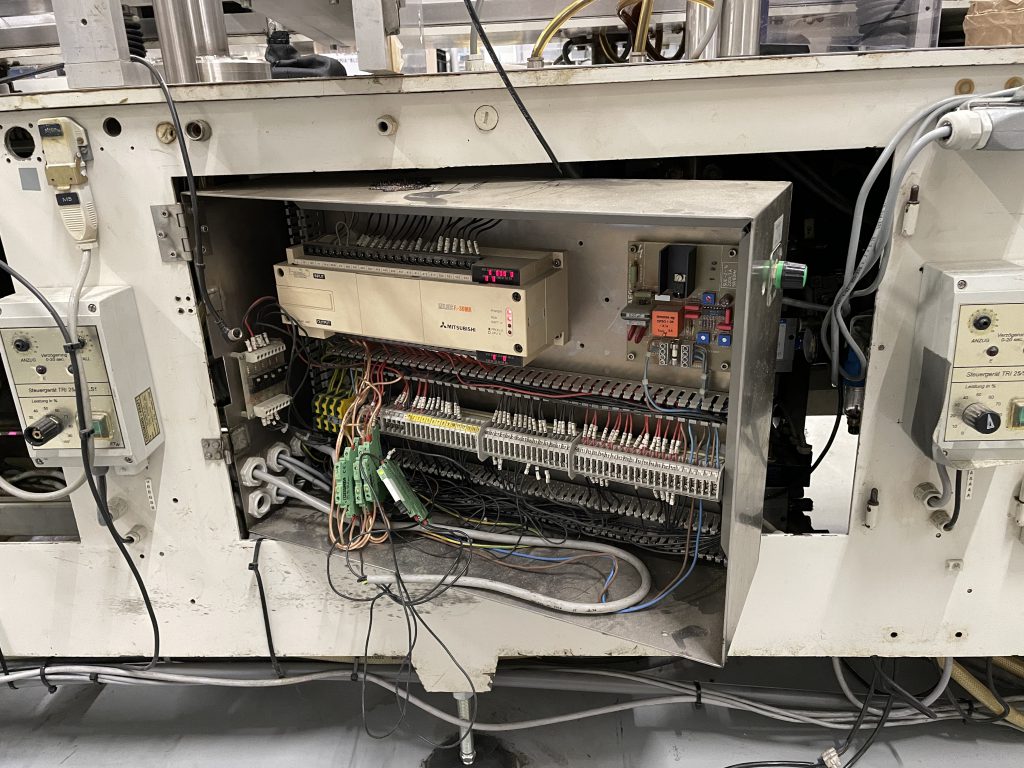

In this project Muns Techniek was asked to modernize the control of a filling machine. The controls were very outdated and a number of parts were no longer available. A significant part of the controls had also become redundant due to adjustments to the machine over the years.

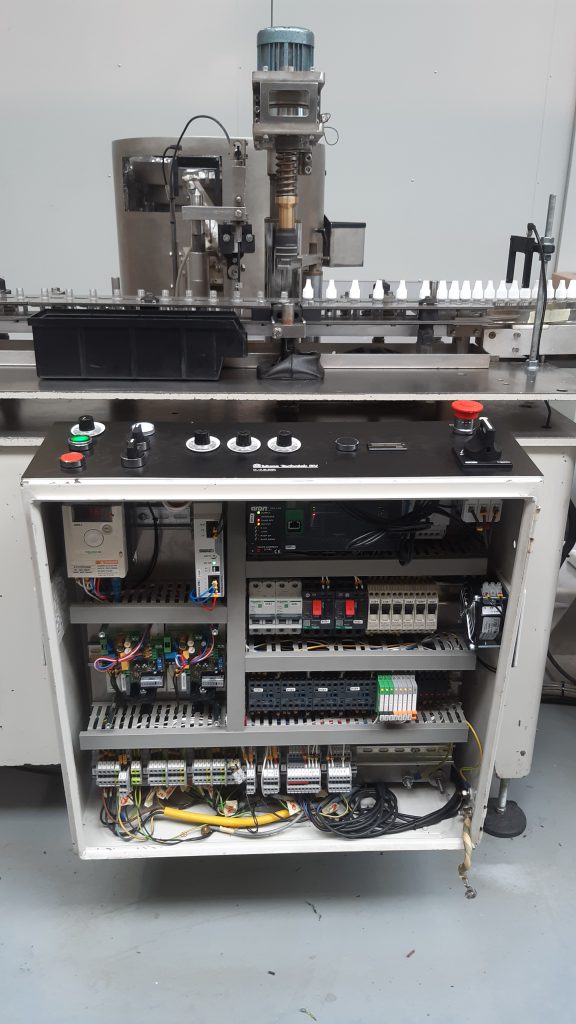

When overhauling and modernizing the drive and control system, Muns Techniek replaced the outdated PLC, frequency drive and thyristor controllers with new models. This allows for the availability and replaceability of the components, both now and in the future.

Additionally, unnecessary components, sensors and cables have been removed, and the remaining sensors and cables have been renewed.

Revising the control system has the advantage that the machine is now future proof for a longer period. Because the unnecessary components have been removed, the two cabinets of the original control could also be integrated into a single cabinet, which makes the system more straightforward.

The system has been cleaned up, modernized and updated. The control system has been simplified and placed into a new operating panel. Future adjustments can now be easily integrated into the new control. This will keep the control simple and uncomplicated in the future.