Recently we were asked by our customer if we were able to modify existing equipment in such a way that the customer could work with it on her project. This is one of the specialties of Muns Techniek; modification to make equipment work to full customer satisfaction.

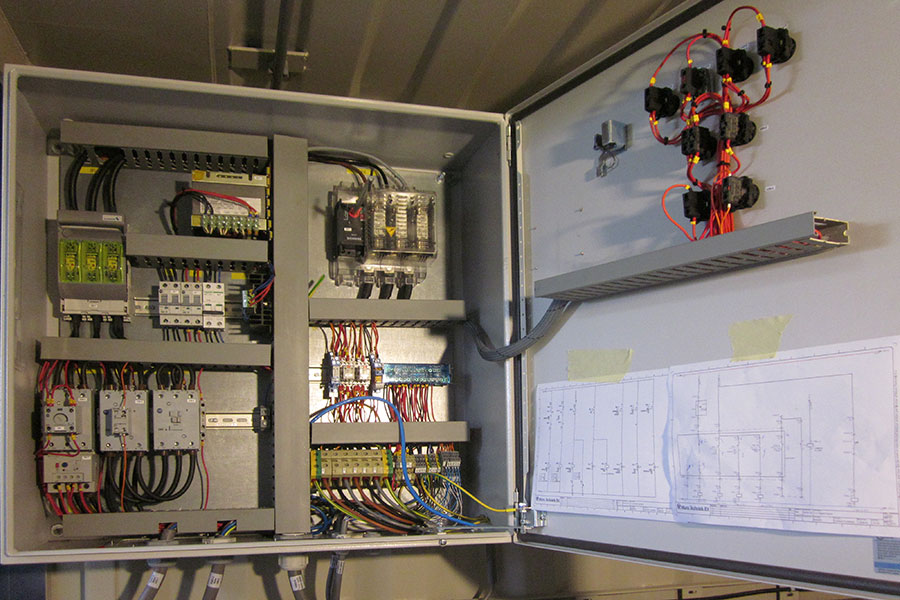

An additional challenge was the lead time to complete everything. Muns Techniek has the flexibility to adapt to these requests instantly. So the old equipment arrived and was inspected, engineering was performed and all required parts were produced and assembled. Four existing winches needed modification so operation with constant tensioning (CT) would be possible and a number of hydraulic operated gate valves needed to be integrated into the hydraulic system and control. New hydraulic manifolds were put in place, hydraulic piping needed modification and electrical control cabinets were re-organized. Finally the HPU was built into a container and the electric control was prepared for integration into a central control unit. Load tests were performed before everything was shipped out to the project site.

All was achieved within the required lead time and to full satisfaction of our customer. Do you have similar modification challenges? Let Muns Techniek help you. Give us a call at +31 (0)183 307000.