- +31 (0)183 307 000

- info@munstechniek.nl

- Mo - Fri: 8:00 - 18:00

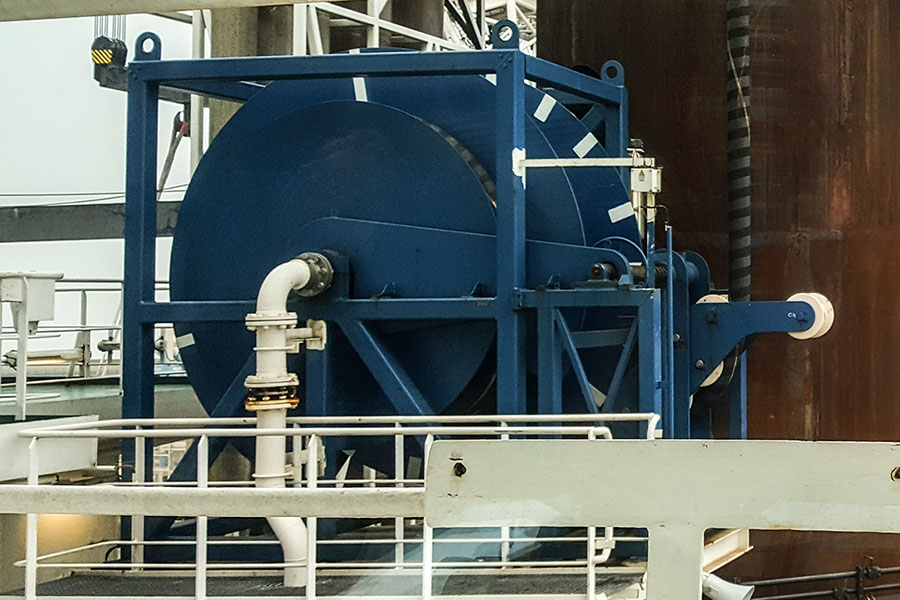

Jan de Nul has special winches on her WTIV “Vole au Vent” (hose reels) with hoses that transport jet water to the spud scans. This water serves to rinse the leg from the soil. Since the delivery of the vessel, there have been regular major failures with this system. Jan de Nul has asked Muns Techniek to make a proposal to make this part more reliable.

Our engineers have completely revised the controls of the frequency drives (VFD) and designed a new CT system. (CT = Constant Tensioning). In addition, we immediately integrated this sub-system into the existing HMI (development Muns Techniek). From now on, it is possible for the “hose reels” to move automatically (synchronized) with the jacking system.

As the new system has been extensively tested in our own workshop by means of a simulation, we were able to carry out commissioning in a relatively short period.

Since our commissioning, the system has been operating fully automatically and without problems or issues. On board it saves 4 people who had to carry out the “hose reels” for this modification.

Nieuw, laatste zin: On board it saves local on the spot checking by 4 persons of the crew.